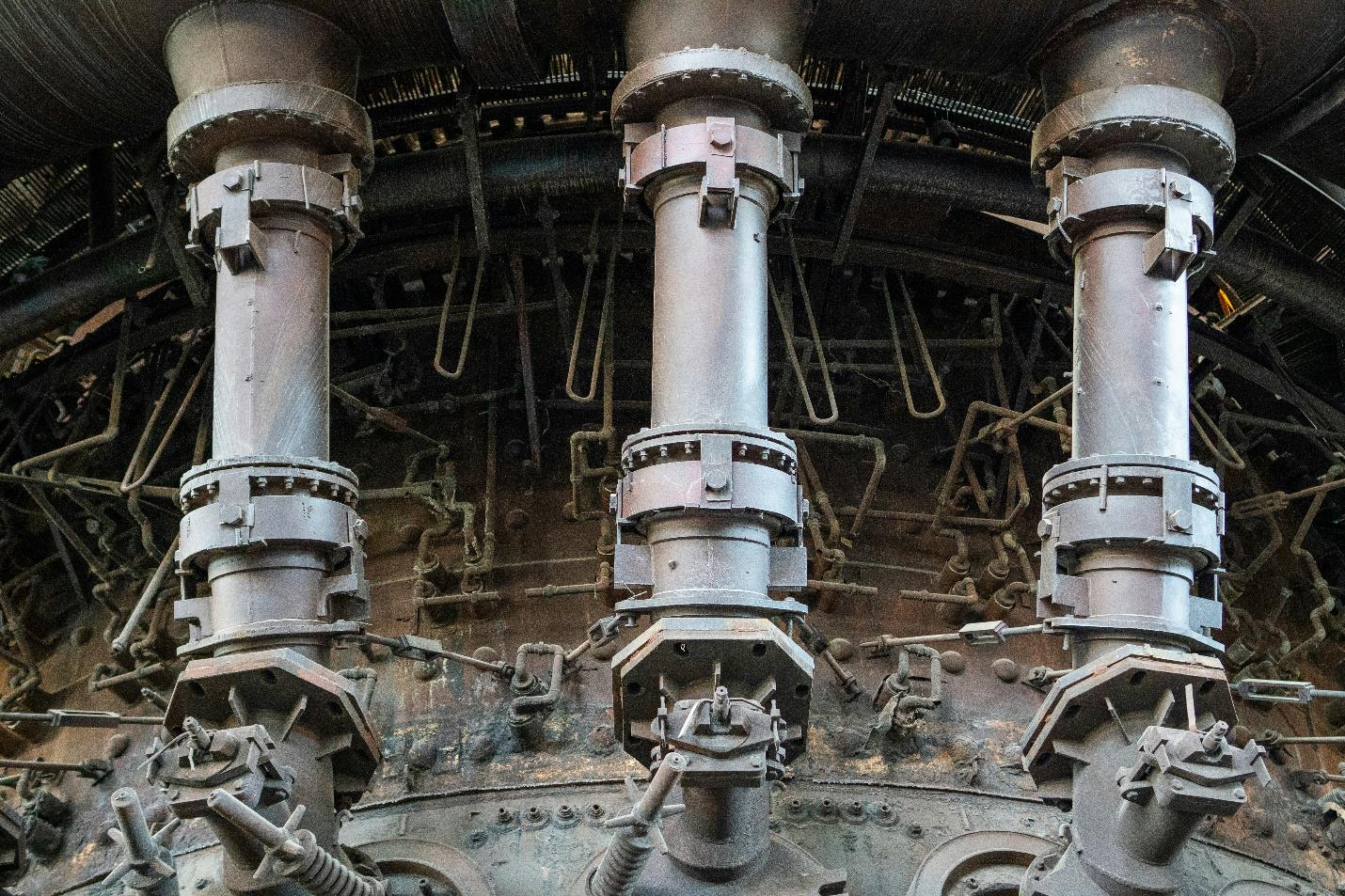

It takes vigilance and discipline on the operator’s part to protect a steam turbine. As an operator of a power plant, you are in a unique position to observe the daily performance of a steam turbine and are likely capable of venturing to guess at the potential major failure that results in considerable unplanned outages, from a much smaller, insignificant issue. This article will highlight some common failure modes and some basic, easily taken actions you can utilize to reduce the risk, maintain operation, and prolong the life of components.

What Causes Turbine Blade Cracking?

Crack growth in blades typically begins with high stress concentrations and subsequently increases due to cyclic loading. Thermal loads from frequent start/stop’s, caustic steam chemistry that could cause stress corrosion cracking, and/or vibrations due to operation at a location other than the design application can lead to an increased risk of crack propagation in steam turbine blades. Erosion due to moisture droplets can contribute to thinning blades, increased local stresses, especially at the leading edges of blades and blade root fillets. Click this site for more information.

For scan inspections for cracks consider executing scheduled visual inspections of blade forms, coupled with nondestructive examinations (NDE), particularly at platform-to-root transitions, fillets, and trailing edges of blades. If indications are found, then coordinate a metallurgical evaluation to confirm the crack mechanism and adjust the operating conditions and/or chemistry that may be causing the cracking. The cost of small repairs are nearly always less than the costs of an unplanned outage with pieces of blades missing.

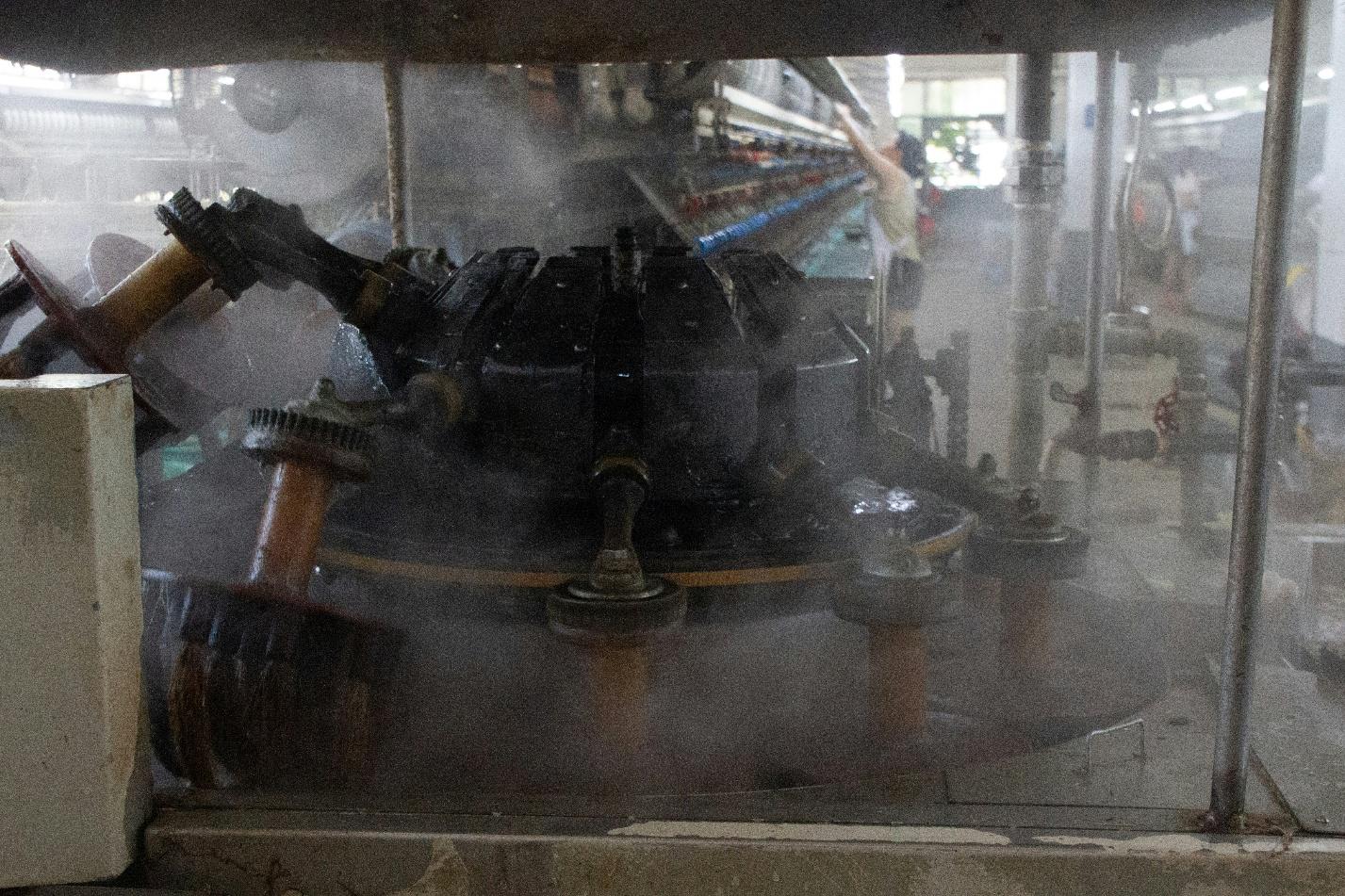

How Deposits Affect Efficiency

Even thin deposits have a speed bumps effect on the aerodynamic surfaces of airfoils. Deposits create surface roughness on the blade, disrupt boundary layers, and change the aerodynamics in the stage. Over time, this will elevate heat rate, cut megawatt output, and could potentially lead to secondary damage (for example, under-deposit corrosion). One easy step is to perform a relatively quick borescope inspection during short outages to help confirm where fouling is occurring and to check on factors of return.

Consider how deposits act subtly to drain performance and reliability:

- Increased surface roughness raises profile losses, which in turn lowers stage efficiency and net MW.

- Leading-edge build-up alters incidence, which effectively drives the turbine to work harder to produce the same load.

- Uneven deposits lead to aerodynamic unbalance which can drive low level vibration or low level seal rubs.

- Under-deposit corrosion pits base metal, thus serving as initiation sites for cracks.

Warning Signs of Rotor Imbalance

The first indicator of rotor imbalance will present itself in your trends. You should expect to see slowly rising amplitudes at running speed (1×) that follow moves in load or temperature. If you see your phase angles stabilize while amplitude grows, suspect mass distribution as this is also one aspect to rotor imbalance, as opposed to alignment. There can be a lot of things that may shift your center of gravity including seal wear, partial deposit shedding or loss of blade mass.

Follow this page https://www.sciencedirect.com/science/article/pii/S0960148123005682 to learn more.

Use vibration analysis to differentiate true unbalance from alignment, looseness or rubs. Use alarms to track operating moves – valve position, condenser vacuum, and swings in superheat. When defining your method to correct for unbalance, arrange it in such a way that you perform a comprehensive inspection, allowing you to understand the source of the problem (rather than just the symptoms) and not repeat previous mistakes.

Preventive Maintenance Steps Explained

The best offense is having a steady set of inspections, clean steam conditions, and defend against fouling with deliberate action. Link each operation to a measurable indicator and provide proof of patterns within a protective environment, while fine tuning your intervals. When damage is discovered, take action to find turbine component repair scoped as early as possible, to limit changes.

Here’s common-sense steps that will result in savings:

- Prescribe tight steam chemistry and carryover control to limit corrosion and deposition.

- Plan to have stage-by-stage inspections conducted with acceptance criteria and go/no-go limits.

- Maintain cleanliness of seals, drains and moisture removal equipment with drainage location to remove as much moisture from the low-pressure sections.

- Check balance and alignment after major transients or outages so you can create a new baseline for the mechanics.

- After each repair or replacement, close the loop with a root-cause-analysis.

How Monitoring Systems Reduce Risk

Modern-day continuous monitoring enables you to understand small changes well in advance of detecting feel through output. Consider utilizing continuous trending for bearing temperatures, axial position, and differential expansion to respond to drift instead of trips. Moreover, innovative intelligent alarms referencing rate of change as opposed to just limits, will help identify issues during “fixable” unbalance events.

Marrying online data to planned offline inspections will help you validate findings against data collection. Over a few operating cycles, you’ll build component histories (each independently) to leverage during the service agreement and scoped downtimes. Ultimately, what this means is a lower potential for surprises, reduced control over heat rate, and a turbine that spends more time creating megawatts rather than stand time.